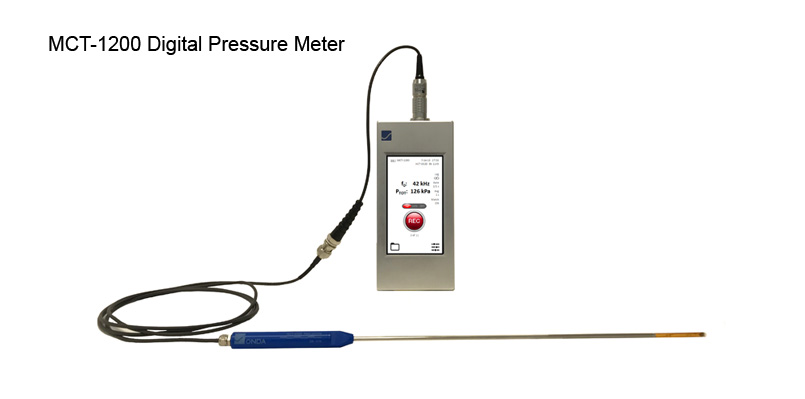

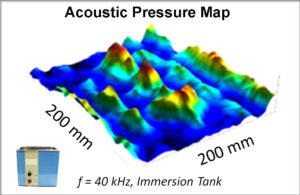

The HCT hydrophone with MCT-1200 Digital Pressure Meter is a trustworthy instrument to characterize and monitor the relative acoustic properties of ultrasonic cleaning systems. Its unique single point sensing design allows localized measurements to generate true 3-dimensional acoustic maps of the cleaning tank.

Some other key features include:

View the MCT-1200 Digital Pressure Meter Datasheet

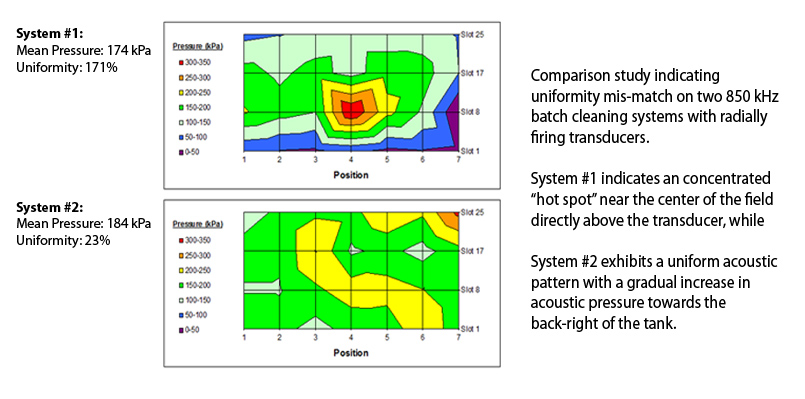

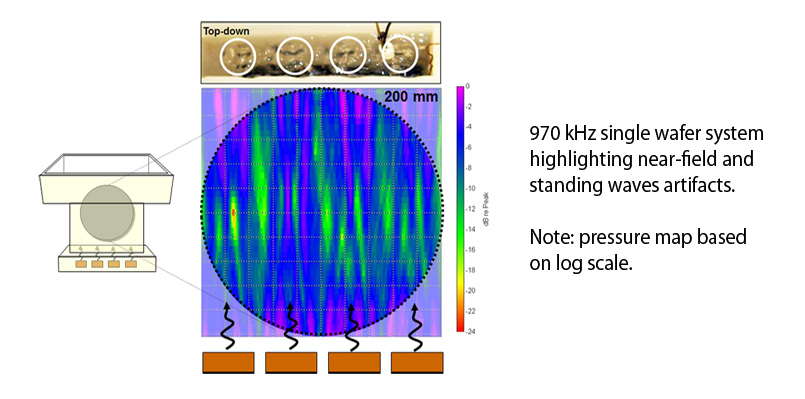

For many ultrasonic cleaning processes, achieving a uniform acoustic field is challenging. This is because there is a broad range of process variables that affect the acoustic field distribution including transducer-to-transducer variation, gas concentration, temperature gradients, flow rate, among others.

Ultimately, this contributes to how well particles are removed directly affecting process yield.

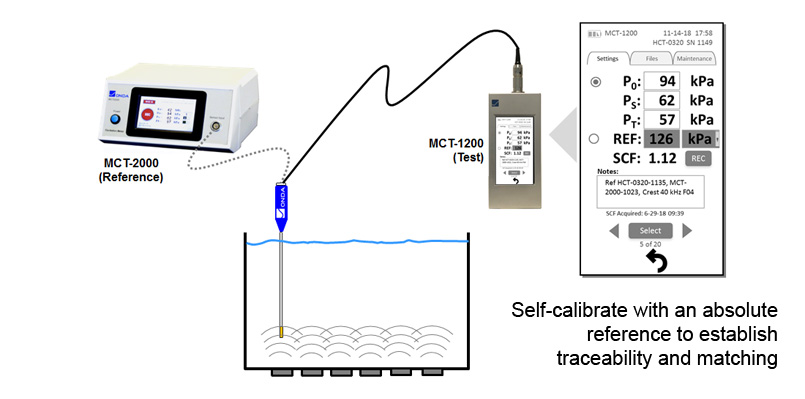

| Measured Parameters | Fundamental Frequency, FO (kHz) Total Pressure, PTOT (kPa or unitless) * * kPa units require self-calibration to absolute reference |

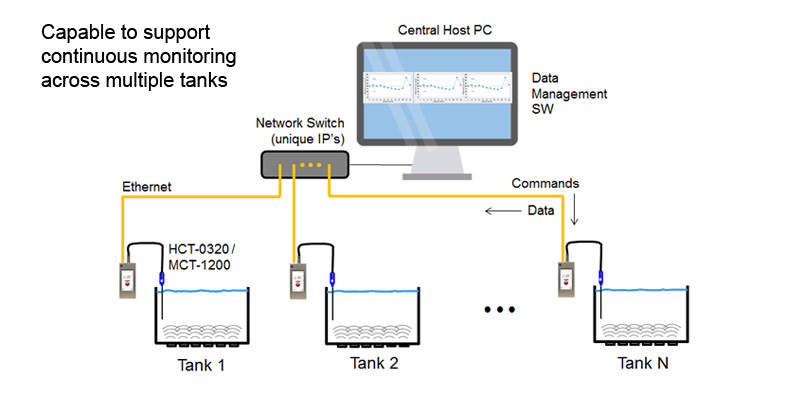

| Data Management | Touch panel display Time averaging interval: 1-60 sec Data logging to local memory Self-calibration to match with reference meter Remote access via Ethernet Real-time data transfer for continuous monitoring |

| Dimensions | 76 mm (W) x 169 mm (H) x 30 mm (D) |

| Power | Rechargeable battery, charger (5 VDC, 3A) |

The HCT-0320 Hydrophone with the MCT-1200 Digital Pressure Meter is an ideal used for routine spot checks to ensure ultrasonic cleaning tanks are optimized. With the use of a hydrophone slide assembly, the setup allows for the characterization of the three-dimensional pressure uniformity to help optimize the cleaning efficiency. Measurements are relative, which is sufficient to compare the acoustic stability over time.

The MCT-1200 includes several features including a touch panel display, data logging to internal memory, data export (ASCII) to a micro-USB thumb drive, and real-time data logging through Ethernet. Data can be rescaled through a self-calibration routine to match with a reference measurement.

For repeatable measurements, the following recommendations should be considered:

Our dedicated specialists are ready to assist you in discovering the ideal product or part for your specific needs. Reach out via phone or email, and we’ll ensure you get precisely what you need for the task at hand.