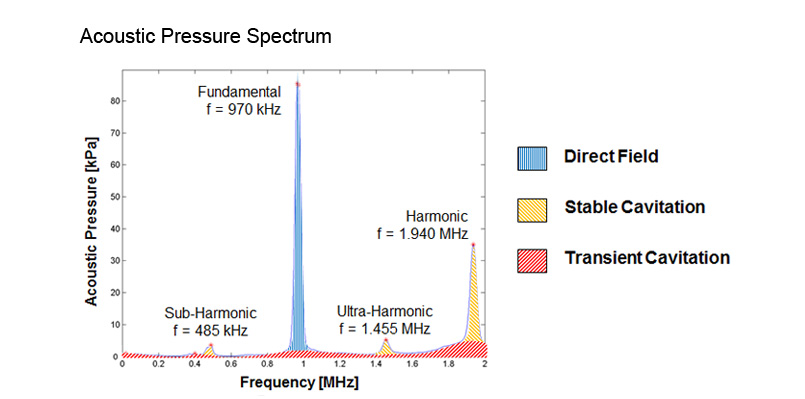

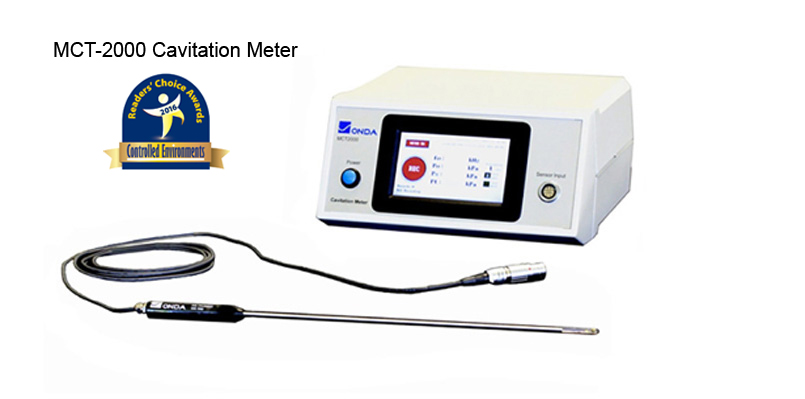

The MCT-2000 combines the power of a high speed digitizer, spectrum analyzer, and advanced microprocessor to produce an acoustic pressure spectrum. Different components in the spectrum are analyzed to quantify the fundamental frequency and pressure from the direct field, stable cavitation, and transient cavitation. Specifically, the pressure within the fundamental frequency peak represent the direct field pressure from the sound wave. The harmonics, sub-harmonics, and ultra-harmonics represent the stable cavitation, or the cavities that oscillate in size and dimension. Finally, the broadband white noise in the spectrum represent the transient cavitation, or the cavities that implode and collapse.

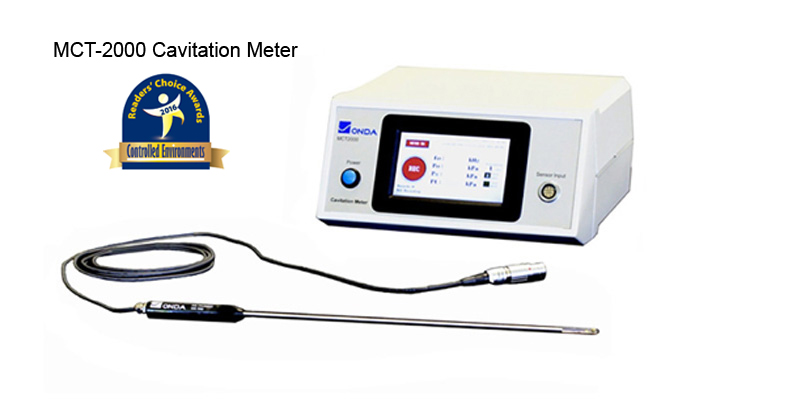

View the Cavitation meter MCT-2000 Datasheet

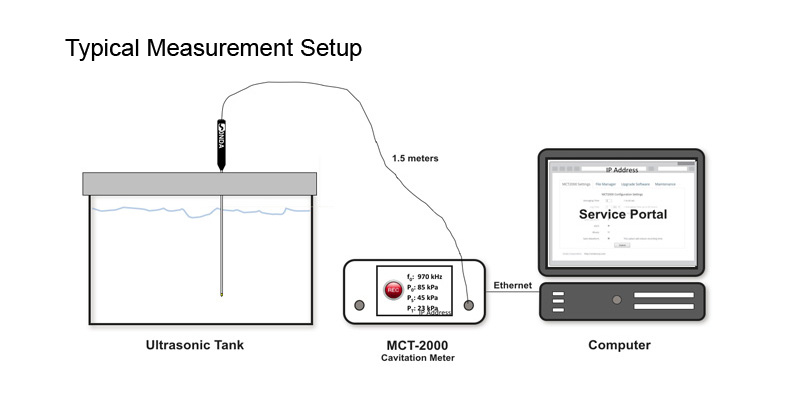

| Measured Parameters | Fundamental Frequency, FO (MHz) Driving Field Pressure, PO (kPa) Stable Cavitation, PS (kPa) Transient Cavitation, PT (kPa) |

| Data Management | Touch panel display Time averaging interval: 1-60 sec Data logging to local memory Save parameters, spectrum, waveform Export as text or binary Remote access for maintenance |

| Dimensions | 232 mm (W) x 113 mm (H) x 215 mm (D) |

| Power | AC Power Plug |

Typically, hydrophones are calibrated annually.

Each Onda hydrophone includes an acoustic calibration certificate which follows IEC 62127-2, by performing the calibration by comparison to a reference hydrophone whose calibration is traceable to NPL. The detailed calibration method is described HERE.

A copy of a traceability certificate for calibrations of hydrophones and preamplifiers at Onda is available upon request.

It may be useful to work backwards.

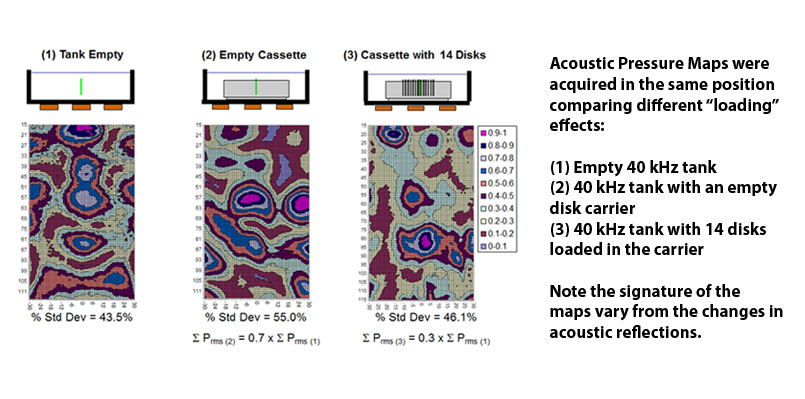

Two parameters commonly used to control a cleaning process include the particle removal efficiency (PRE) and the localized damage. These parameters are often determined by visual, optical, or chemical methods, counting and binning particle or defect information. To translate these parameters to the acoustic performance, a correlation study to determine how process variables such as frequency, generator power, chemistry, temperature etc. influence the acoustic parameters including the direct field, stable cavitation, and transient cavitation pressure.

For reference, there are published studies available in RESOURCES.

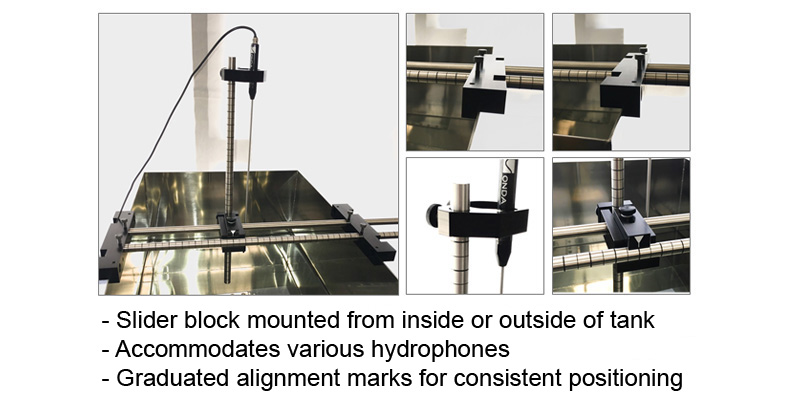

For repeatable measurements, the following recommendations should be considered:

Check your measurement instrument by routinely testing it in a stable reference tank under controlled conditions. Acoustically calibrate the instrument on a periodic basis (e.g., annually). For more information about Onda’s calibration services, please CONTACT US.

Our dedicated specialists are ready to assist you in discovering the ideal product or part for your specific needs. Reach out via phone or email, and we’ll ensure you get precisely what you need for the task at hand.