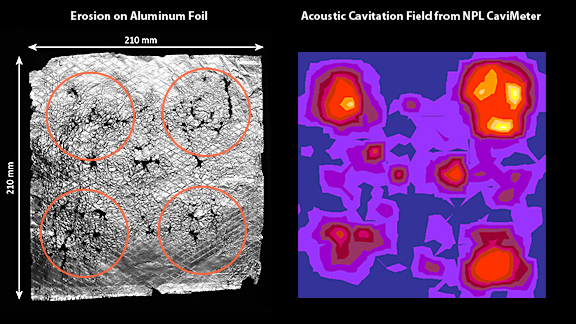

Ideal for measuring acoustic cavitation in ultrasonic wafer cleaning tanks, the CaviMeterTM was developed by the National Physical Laboratory (NPL) to measure the acoustic emissions generated by cavitation. Cavitation is the growth, contraction, and collapse of micro-bubbles (or cavities) within a liquid media in response to a driving ultrasonic field. The amount of energy from the implosion of a cavity is sufficient to overcome particle adhesion forces and hence is used for ultrasonic cleaning and other sonoprocessing applications such as semiconductor wafer processing. Excessive cavitation energy can also damage the silicon surface and films of a wafer substrate, which makes it essential to develop and control a process window through careful measurement.

View the NPL Cavimeter Datasheet

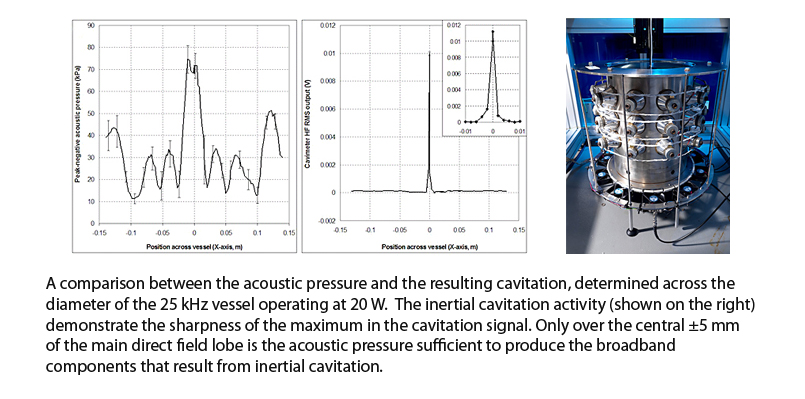

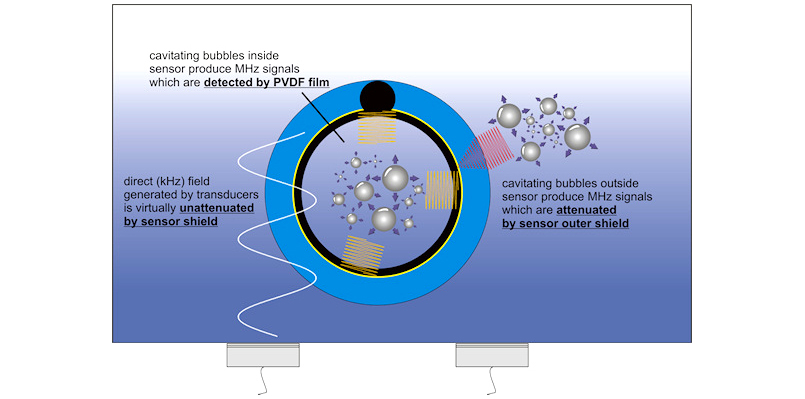

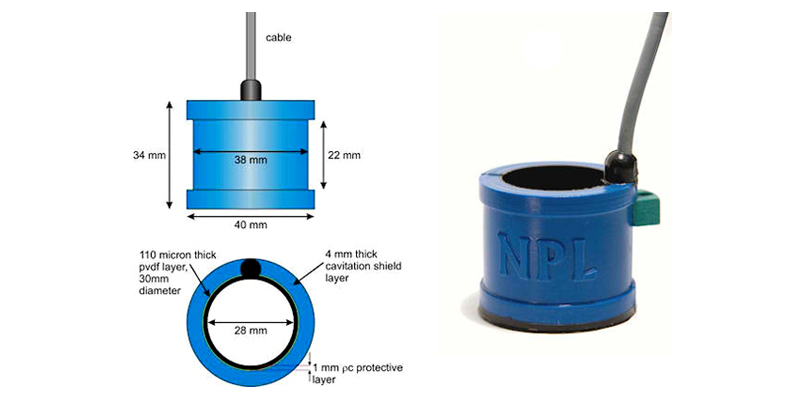

The unique CaviSensor cavitation detector is designed to measure both the broadband acoustic signal generated from cavitation and the direct field at the drive frequency in the ultrasonic cleaning tank. The hollow cylindrical shaped sensor is constructed with a polyurethane shell lined with a piezoelectric polymer film. While the polyurethane “shields” the high frequency broadband signals (High Frequency, or HF) generated by cavitation outside the cylinder, the piezoelectric film detects the localized cavitation along the inner central line of focus. The piezoelectric film also measures the direct field signal at the fundamental frequency (Low Frequency, LF), which is transmitted through the polyurethane. Both the HF and LF signals are then processed by the CaviMeterTM cavitation measuring system to quantify the level of cavitation and direct field pressure.

| Measured Parameters | Fundamental Frequency, FO (MHz) Driving Field Pressure, PO (kPa) Stable Cavitation, PS (kPa) Transient Cavitation, PT (kPa) |

| Data Management | Touch panel display Time averaging interval: 1-60 sec Data logging to local memory Save parameters, spectrum, waveform Export as text or binary Remote access for maintenance |

| Dimensions | 232 mm (W) x 113 mm (H) x 215 mm (D) |

| Power | AC Power Plug |

Our dedicated specialists are ready to assist you in discovering the ideal product or part for your specific needs. Reach out via phone or email, and we’ll ensure you get precisely what you need for the task at hand.