Our range of innovative, dependable products is specifically designed and tested ensuring accurate performance and reliable measurements.

Onda consistently offers the latest technology updates and industry trends, carefully curated by our team of knowledgeable experts.

Watch as Onda’s MCT-1200 Digital Pressure Meter compares to the Sonocheck Vials by Healthmark.

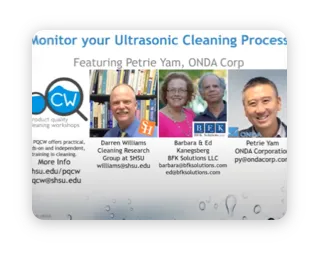

PQCWebinar, September 9, 2020 – Ultrasonic cleaning is a dynamic process, and there are ways to monitor it that are more responsive and informative than the traditional metal foil test. With Onda technology one can systematically monitor and control each parameter that impacts the ultrasonic cleaning process.

The presentation by Ondasonics focuses on innovative in-situ cavitation measurements using a wireless sensor array, specifically applied to the field of megasonic photomask cleaning.